KNOWLEDGE

![]()

Since the creation of the BirdyFish, our production structure based in Saint-Herblain, Loire-Atlantique, has continued to evolve to allow our foil boat to fly you.

COMPOSITE

How to give birth to the foil boat BirdyFish ?

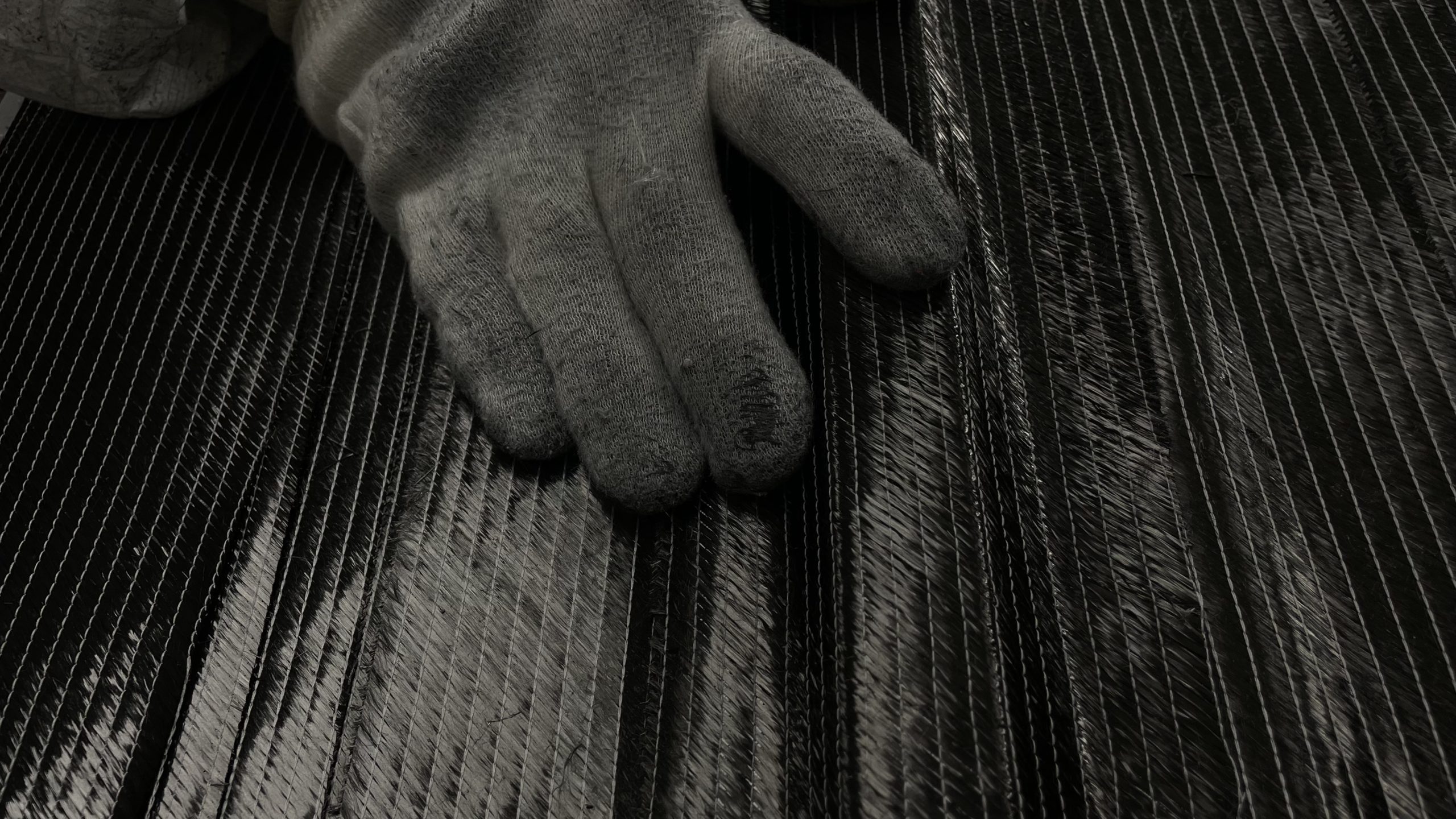

First of all thanks to our technical team ! Experts in composite manufacturing processes, our team cover all stages of Gelcoat manufacturing up to fittings.

Using products sensitive to its environment, glass/polyester for the hull and carbon/epoxy, for the appendages, a temperate zone between 19°c and 21°c, allows us to control the infusions throughout the year and to to have an optimal production quality whatever the conditions.

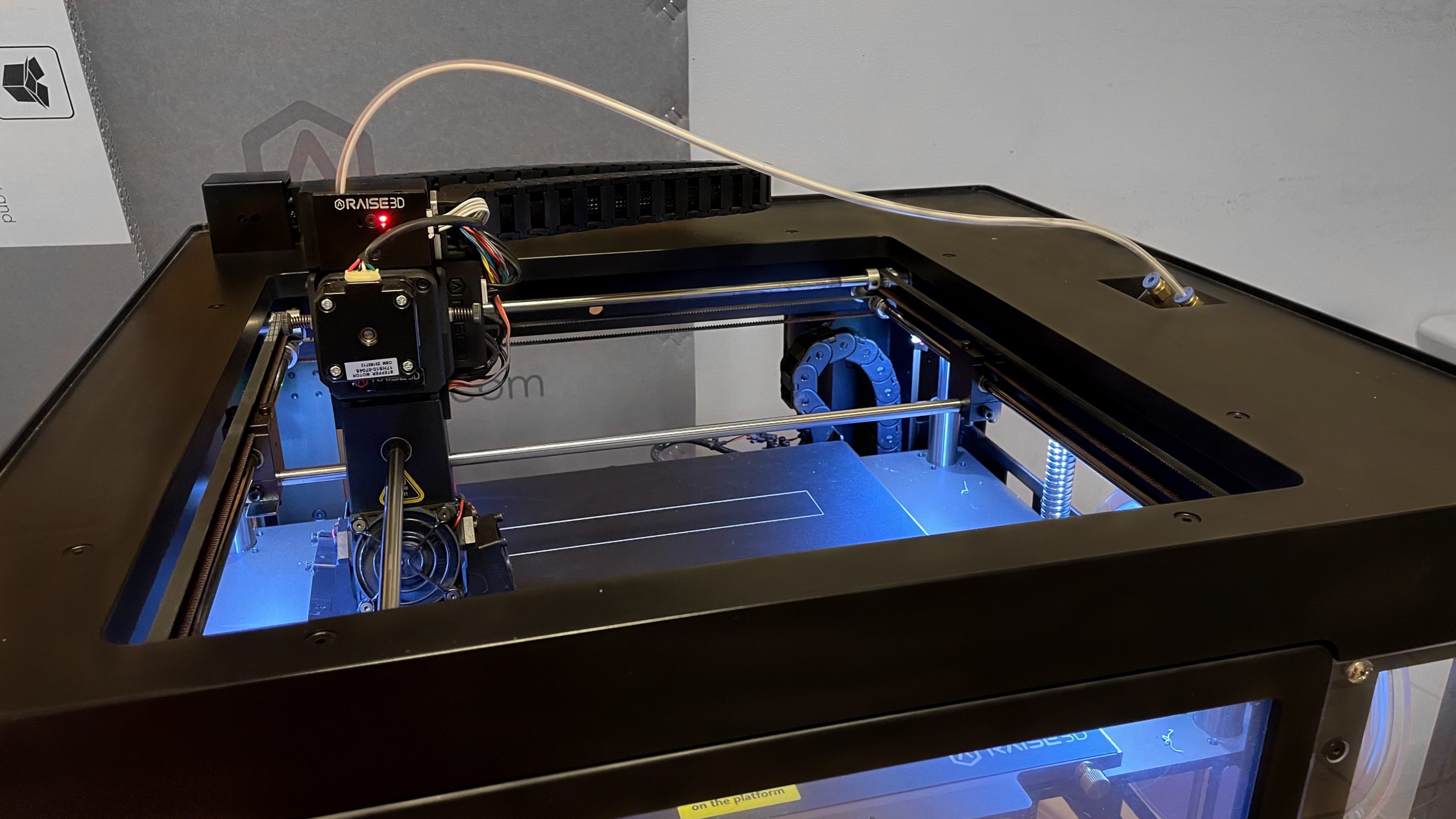

RAPID PROTOTYPING

Continuous improvement is the watchword in our workshops.

Our teams are constantly proposing improvements to processes, workstation ergonomics and the product.

We can go from the idea to the realization of tests thanks to additive manufacturing. This in-house technology allows us to carry out rapid prototyping in a very short time.

DAILY ISSUES

One issue, health, safety and environment.

We are committed to putting our employees in the best possible conditions by providing all the necessary means of protection and by regularly raising awareness.

At our level, we try to reduce our environmental impact as much as possible (biosourced resin, favouring local collaborators, limiting waste volumes, etc.)

A QUESTION ?

Contact-us !